Date: April 2 • 2026

End date: May 21 • 2026

Online: April 17 to May 21, 2026

Opening Reception: April 10 • 7 – 9 pm • more info

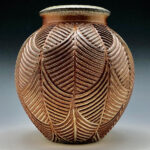

Ceramics in the Atrium

This exhibition highlights the various atmospheric firings Tri-City Potters has participated in as a group and the artistic growth our members have experienced through these opportunities.

In recent years, the Tri-City Potters have organized workshops and participated in sawdust, soda and raku firings along with electric and gas kiln firings. This exhibition offers a perfect opportunity to showcase our members’ work and share our collective learnings with the local ceramic community.

Oxidation firing is a ceramic process in which sufficient oxygen in the kiln allows fuel to burn completely, preventing carbon buildup and ensuring predictable results. It is favoured for producing bright, consistent glaze colours and has become more precise with advances in kiln technology. It is mostly used in electric kilns.

Raku firing is a low-temperature technique in which ceramic pieces are removed from the kiln when they are red hot and the glaze is molten. They are immediately thrust into a container of combustible materials, such as sawdust, and the source of oxygen is cut off. The resulting flames take oxygen from the oxides in the glazes and produce brilliant metallic colours, shiny or matte, depending on the glaze. The pieces are then removed and cooled with water to stop the reduction process. Raku is prized by potters for its dramatic process and unique, often surprising results.

Reduction firing is a ceramic process in which the oxygen supply in the kiln is limited so that the flames draw the oxygen from the oxides in the glazes to create rich, vibrant colours not typically achieved through other firing methods. It is valued by artists for the distinctive surfaces, textures, and finishes it produces.

Sawdust firing is a low-temperature, primitive technique that uses burning sawdust to create a reducing atmosphere, producing smoky surfaces, darkened tones, and organic patterns. Though the results are unpredictable, this quality, often enhanced by adding materials like leaves or salts, is what makes the technique especially valued for its unique decorative effects. The pieces are usually burnished before firing to produce surface shine and limited water resistance.

Soda firing is a ceramic process in which a soda ash solution is sprayed into the kiln at high temperature, causing sodium vapour to react with silica in the clay and form a natural glaze on the surface. Reduction also takes place, bringing out colours in the glazes.

Wood firing is a ceramic process in which wood is the only fuel used to bring a kiln to a high temperature, requiring continuous manual care over hours or even days. The pieces are coloured by heat, ash, smoke, and constantly shifting oxidation and reduction atmospheres, resulting in richly varied and natural surfaces.

Website: tricitypotters.ca

Facebook: @tricitypotters